Our Quality Service

Our vision is to deliver excellent comprehensive business support service, delighting customers and adding continuous significant value and growth to our work. Our services are placed at highly competitive prices to full-fill all your expectations. We believe in total customer satisfaction by providing full-fledged support. Also we want to maintain a long term business relationship with you and taste the flavours of success along with you by playing on your side.

We are specialist in working in bright Zinc Plating, Nickel Plating, Travelent Blue, Travelent Yellow, Cadmium Plating, S.S Electro Plating, Zinc – Nickel plating and PTFE (Xylan Coating). We are also eligible to provide 35 to 40 microns on Xylan Coating and 25 to 30 micron on Zinc- Nickel Process.

Zinc Nickel plating

Zinc-nickel plating is one of the best corrosion resistant finishes available offering over 5 times the protection of conventional zinc plating and up to 1000-1200 hours of red rust salt spray test performance. This plating is a combination of a high-nickel zinc-nickel alloy can be used as a pre-coat for xylan ptfe coating.

Cadmium Plating

Cadmium plating is a type of coating process that offers technical benefits such as outstanding corrosion resistance, even in high-salt and low-thickness environments. Cadmium is the by product of the production of zinc.Cadmium yellow and cadmium green also helps to increase the life expectancy of the product and give more time of salt spray test then zinc plating.

Electro Polishing

Electro polishing is an process that removes a controlled amount of material from the surface of stainless steel and other metal alloys. It is the process of smoothing metal surfaces to make them highly corrosion resistant. This is a method of producing simultaneous brightening, smoothing, deburring, cleaning, and passivation on stainless steels or other metal alloys.

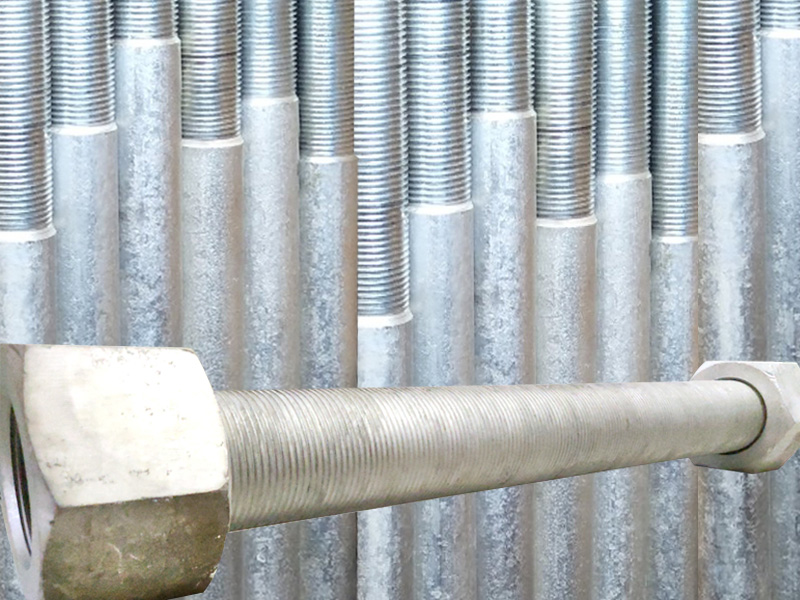

Zinc plating

Life expectancy of zinc plating / electroplating to be outdoors in an industrial atmosphere. We currently plate the product with zinc-metal which provides about 300-350 hours approx till red rust. 8-10 microns can be provided. Travelent blue & Travelent yellow also helps to increase the life expectancy of the material.

Nickel Plating

Nickel plating provides a unique combination of corrosion and wear resistance. It can add brightness, lustre and appeal. It also provides excellent adhesion properties for subsequent coating layers, which is why nickel is often used as an 'undercoat' for other coatings, such as ptfe (xylan).

PTFE Xylan Coating

Zinc-nickel plating is one of the best corrosion resistant finishes available offering over 5 times the protection of conventional zinc plating and up to 1000-1200 hours of red rust salt spray test performance. This plating is a combination of a high-nickel zinc-nickel alloy can be used as a pre-coat for xylan ptfe coating.

Trivalent yellow

Thick trivalent yellow passivate is getting more and more popular with our customers due to its enviromentally friendly basis and a great protection and attactive very light yellow colour with a hint of irredescence. which helps to provide an increase of salt spray test on the material.on average a protection of 140 -200 hours salt spray to white corrosion.

Trivalent Blue

Blue Passivation Process is a single shot concentrated Trivalent Passivation process which provides instantly, an intense blue colour on zinc and zinc alloy platings which achieves excellent corrosion resistance.

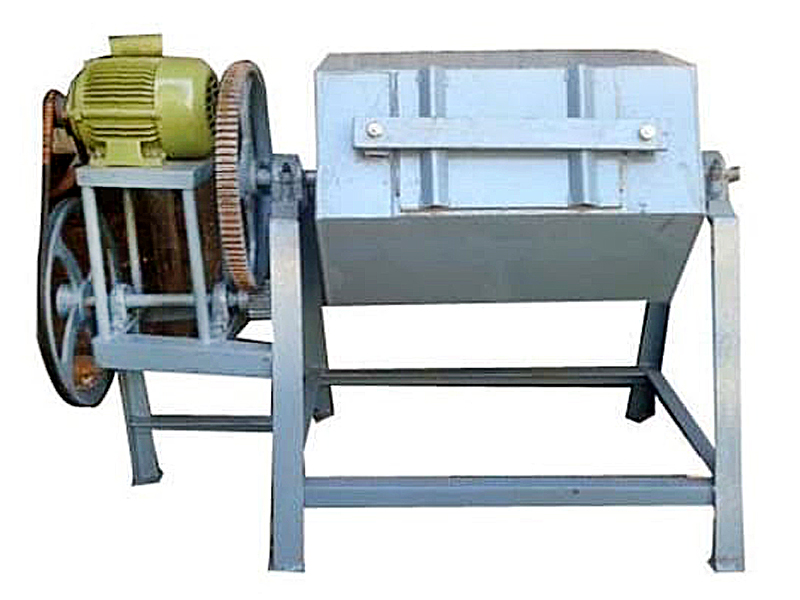

Drum Polishing

Drum Polishing is one finishing loose abrasive process, used to generate surfaces with very high tolerances in geometry, surface integrity, and roughness characteristics. This smoothness is obtained by rubbing the surface with the polishing particles with a rotating disk.